Advanced Milling

NCI, PMG, SMG, PMA, NVG, MMG, AMG, MPG

Duration: 5 days – (40 Hrs)

Overview:

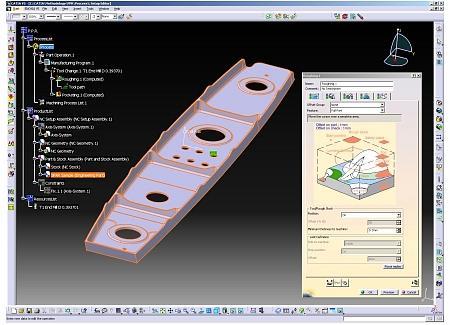

At the end of this course, students will learn to utilize the CATIA V5

NC Manufacturing platform with 2.5 to 5+ Axis machining capability for generating NC programs.

Participants will learn to define and manage prismatic and surfacing

operations, being aware of all capabilities in terms of strategies,

parameters and transition paths. They will also learn how to define and

manage NC programs dedicated to machining parts designed with Surface or

Solid geometry using the CATIA V5 PMG, SMG, MMG and AMG workbenches. Finally,

users will learn how to efficiently generate and manage NC data output.

Prerequisites:

Participants must possess basic working knowledge of CATIA V5 and ought

to be proficient in Sketcher, Part Design and Assembly Design. Basic

knowledge of machining practices and exposure to CATIA V5 NC benches is

required.

Topics Covered:

|

A.M. |

P.M. |

|

Day 1 |

|

*

CATIA V5 – NC Mfg Workbench Presentation – 30 mins.

* Part Operation, Manufacturing Programs – 30 mins.

* Facing Operation – 60 mins.

* Tool Path Replay - 30 mins

* Pocketing Operation – 60 mins.

* Curve following – 30 mins. |

* Profile contouring – 60 mins.

* Groove Milling – 30 mins.

* Point to point Operation – 30 mins.

* Transition Paths (macros) – 60 mins.

* Axial Operations – 60 mins. |

|

Day 2 |

|

* Auxiliary Operations – 30 mins.

* PP commands – 30 mins.

* Tool Path Verification – 30 mins.

* Tool Management – 60 mins.

* Prismatic Roughing – 45 mins.

* Sweep Roughing Operation – 45 mins. |

* Roughing Operation – 60 mins.

* Machining/Slope Area Creation –

30 mins.

* Zone and Offset Area creation – 30 mins.

* Rework Area Creation – 60 mins.

* Sweeping Operation – 60 mins. |

|

Day 3 |

|

* Pencil Operation – 30 mins.

* Z-level Operation – 60 mins.

* Machining Axis change – 30 mins.

* Machine Rotations – 30 mins.

* Contour-driven Operation – 60

mins.

* Process Views - 30 mins |

* Isoparametric Machining – 60 mins.

* Auto sequencing – 30 mins.

* Spiral Milling Operation – 60 mins.

* Generating Outputs (APT Source - NC Code) – 45 mins.

* Multi-Axis Machining Concepts - 45 mins. |

|

Day 4 |

|

* Multi-Axis Sweeping Operation – 60

mins.

* Multi-Axis Contour Driven Operation – 60 mins.

* Multi-Axis Curve Machining – 60 mins.

* Multi-Axis Isoparametric Machining – 60 mins. |

* Multi-Axis Drilling Operation –

60 mins.

* Multi-Axis Tube Machining Operation – 60 mins.

* Multi-Axis Flank Contouring – 120 mins. |

|

Day 5 |

|

* Multi-Axis Helix Machining – 60

mins.

* Cavities Roughing - 60 mins.

* Power Machining - 90 mins.

* Feature Recognition PMA - 60 mins. |

* Tool Path Editor - 30 mins

* PP Table Modifications - 30 mins.

* Machining Processes - 60 mins.

* Design Change Management - 60 mins.

* User questions and training wrap up – 30 mins. |

Download Training Course Brochure..>>

For complete course schedules and pricing, kindly

contact us at:

training@camcoe.com