CAMCOE's NC Auditing

service is a documented

assessment of the usage of CATIA V5 NC solutions at your facility and is

conducted to determine if your current manufacturing setup is on par with best industry practices. The report

recommends potential solutions for improvement.

CAMCOE's NC Auditing

service is a documented

assessment of the usage of CATIA V5 NC solutions at your facility and is

conducted to determine if your current manufacturing setup is on par with best industry practices. The report

recommends potential solutions for improvement.

How is the NC Audit performed ?

A typical NC audit consists of 4 days on-site for data and information

collection and 4 days off-site for analysis and report documentation.

What are the benefits of an NC

Audit ?

An NC audit enables management to evaluate the usage of the

software and highlights improvement potential, including savings. It

will help identify and prioritize specific improvement actions to

implement. The audit report also contains recommendations that help a

company gain insight and knowledge on how similar or other companies are

best utilizing the software.

How often should an NC Audit be

done ?

An NC audit should be ideally done once every two or a maximum

of three years to gain full advantage of current industry practices,

software improvements, functionality usage, new methodologies, advanced

techniques etc.

Which companies would benefit an

NC Audit ?

Companies both small and large will benefit from an NC audit. No

matter whether you have 2 people or 200 people using the software, the

objective is the same - To asses your current NC process and recommend

areas of improvement.

What is involved in an NC Audit

?

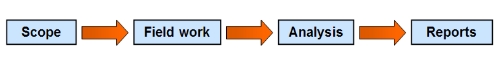

There are four distinct stages to an NC auditing assignment,

Scoping, Field work, Analysis and Reporting as detailed below.

Scoping and audit plan:

The auditor who is an NC specialist determines the main areas of focus

and any areas that are explicitly out-of-scope. Information sources at

this stage include background review, previous audit reports and,

sometimes, subjective impressions that deserve further investigation.

The scope is broken down into greater levels of detail, usually

involving the generation of an audit work plan.

Fieldwork:

Work is then done on-site by gathering data and evidence

by interviewing NC programmers, Engineers, Staff and Managers, reviewing

NC Programs, CATIA files, observing complete machining processes etc.

Analysis:

This step involves sorting out, reviewing and putting together all the

data and information collected on-site. Identification of problem

areas, improvement techniques, bottlenecks, activity time study are

performed. The analysis is done off-site.

Reporting:

The NC audit report document identifies any areas of

weaknesses in the NC Programming process, any improper use of the

software, suggests software, hardware, licenses, training etc that could

potentially provide significant improvements and savings.

Contact us today to learn more about

how a NC audit can help you :

services@camcoe.com