|

|

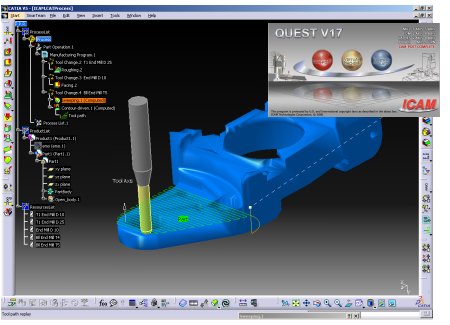

CATIA V5 / CAMPOST - Implementation Courses

Advanced Course

NCI, PMG, SMG, AMG, CAMPOST

Duration: 5 days – (40 Hrs)

Overview:

This course is tailored towards users who are already familiar with the

CATIA V5 basic NC manufacturing workbenches (NCI, PMG, SMG). Users

completing this course will learn to use the CATIA V5 / CAM-POST

integrated platform for 2.5 to multi-axis (AMG) machining and also learn

to develop and use ICAM post processors for generating multi-axis NC

programs. Users will learn to define and manage prismatic to multi-axis

machining operations, being aware of all capabilities in terms of

strategies, parameters, transition paths, toolpath output customization

etc. They will also learn how to define and manage NC programs dedicated

to machining parts designed with Surface or Solid geometry using the

CATIA PMG, SMG and AMG workbenches. Next, users will learn to apply and

use their CATIA tool path output by developing and customizing multi

axis NC post processors with CAM-POST. Finally, they will be mentored on

best practices approach for integrating CATIA V5/CAM-POST to efficiently

generate and manage NC code output for unique multi axis milling machine

/ controller combinations.

Prerequisites:

Participants must possess basic knowledge of working in a CATIA V5

environment with proficiency in Sketcher, Part Design, Assembly Design,

PMG, SMG, AMG. Good knowledge of machining practices is required.

Topics Covered:

|

A.M. |

P.M. |

|

Day 1 |

|

*

CATIA V5 – NC Manufacturing Review – 45 mins.

* PMG Workbench Review – 90 mins.

* Axial Operations – 45 mins.

* Tool Path Verification – 30 mins.

* Generating Outputs (APT Source – NC Code) – 30 mins. |

* SMG Workbench Review – 120 mins.

* AMG Workbench Review – 120 mins. |

|

Day 2 |

|

*

Auxiliary Operations – 30 mins.

* Transition Paths (macros) – 45 mins.

* PP commands – 45 mins.

* Machining/Slope Area Creation – 30 mins.

* Zone and Offset Area creation – 30 mins.

* Applying Feeds, Speeds and Coolants – 30 mins.

* Tool Catalog - Creation/Import/Use – 30 mins. |

* Rework Operations – 30 mins.

* Machining Axis change – 30 mins.

* Machine Rotations – 30 mins.

* Tool path Editor – 45 mins.

* CATIA NC Mfg internal variables – 30 mins.

* PP Table Customization – 30 mins.

* Part Family Machining Methodology – 45 mins. |

|

Day 3 |

|

* Creating Machining Processes –

60 mins.

* Understanding Manufacturing View – 30 mins.

* Creating/Using Machining Patterns – 30 mins.

* Using Parameters in CATIA NC – 60 mins.

* Using Publications in CATIA NC – 60 mins. |

* CAM-POST – Post Processing

Introduction – 60 mins.

* Creating Posts with CAM-POST Wizard – 60 mins.

* CAM-POST Quest and Gener Use – 60 mins.

* Using RMD for macro creation – 60 mins. |

|

Day 4 |

|

* Registers and Formats – 60 mins.

* Introduction to Macro Language – 120 mins.

* Using SDL for macro creation – 60 mins. |

* More user defined macros – 60

mins.

* Startup/Shut down Procedures – 60 mins.

* Introduction & Use of PP Functions – 120 mins. |

|

Day 5 |

|

* CATIA/CAM-POST – NC Mfg

Customization – 240 mins.

Tool Length Compensation, Tool Diameter Compensation,

Fixture Compensation, Canned Cycles, Linear and Circular

Interpolation, Home Point, Feedrates, Spindle commands, Coolant

commands, Arc fitting, Rotary Heads, Rotary Tables, Lintol

Rotary Turnaround, High Speed Machining, RTCP etc. |

* CATIA / CAMPOST Settings &

Administration – 120 mins.

* Best Practices Approach for NC Data Output – 60 mins.

* User Question and Answer Session – 60 mins. |

Download Training Course Brochure..>>

For complete course schedules and pricing, kindly

contact us at:

training@camcoe.com

|