|

CATIA V5 - Primary Course

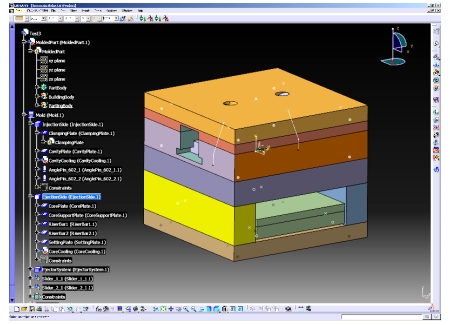

Mold

Tooling Design Course

PDG, ASD, GSD, GDR, CCV, MTD

Duration: 5 days – (40 Hrs)

Overview:

CAMCOE provides

this customized course as an end to end solution from the design of the

molded part to the manufacturing of the associated mold tooling. This

course has been specifically designed for NC Programmers, Engineers and

Management people who require complete CATIA V5 fundamental and mold

design skills to be cooperatively used downstream with PMG, SMG and AMG

NC Manufacturing workbenches of CATIA V5.

At the end of this

course, participants will be fully skilled in creating sketches, solids,

surfaces, assemblies, drawings, cores and cavities and mold tooling

which are all necessary to machine molds with the CATIA V5 NC

manufacturing solutions.

Prerequisites:

Participants

must possess basic working knowledge in Part Design, Assembly and

Surface Design.

Topics Covered:

|

A.M. |

P.M. |

|

Day 1 |

|

* CATIA V5 Mold Tooling – Introduction – 60

mins.

* Sketcher and Part Design Review - 180mins.

Operation, Profile, Constraints, Creating Points, Lines,

Circles, Sketching Pre-Defined Profiles, Creating Pads, Pockets,

Thin solids, Shafts |

* Part

Design Review continued.. - 240 mins

Creating Holes, Fillets, Draft, Chamfer, Shell, Ribs, Patterns,

Rectangular, Circular, User, Boolean Operation, Part

Modifications |

|

Day 2 |

|

* Wireframe

and Surface Design Review - 240 mins

Wireframe: Points, Lines, Circles and Planes,

Extrusion, Offset, Sweeping, Filling, Blending, Lofting,

Boundary, Intersection, Open Body, Part Body, Join, Split,

Fillet, Translate, Project, Extract |

* Assembly

Design Review - 240 mins

General Assembly process, Inserting Components,

Compass control, Replacing Components, Moving Components,

Constraints, Space Analysis, Measuring Tools, Flexible and Rigid

Assembly |

|

Day 3 |

|

* Drafting

Overview - 240 mins

View Creation Wizard, Primary, Section, Detail,

Clipped, Break, Text and Dimensioning, Drawing Standards,

Saving CATDrawing, Printing |

* Core and

Cavity Design - 240 mins

Importing a Model, Comparing Two Molded Parts,

Bounding Box, Main Pulling Direction with and without Draft,

Pulling Direction for Sliders, Transferring Elements, Splitting

a Face, Aggregating Surfaces, Exploding the View, Orienting

Faces, Parting Line, Chaining Edges, Parting Surface, Light

Surface |

|

Day 4 |

|

* Core and

Cavity Design contd.. - 240 mins

Sectioning, Creating Section Planes,

Creating 3D Section Cuts, Manipulating and Positioning Planes,

Using the Edit Position and Dimensions Command, Displaying

Boundaries of Surfaces, Smoothing Edges, Analyzing the Pulling

Direction Searching Fillets, Reducing the Fillet Radius |

* Mold

Tooling Design – 240 mins

Defining the Mold Base, Splitting the Core and

the Cavity, Adding and Removing Plates, Inserting Components,

Positioning Ejector Pins on a Mold Base, Creating a Gate,

Creating a Runner, Creating a Coolant Channel, Positioning a

Slider |

|

Day 5 |

|

* Mold

Tooling Design contd.. – 240 mins

Holes, Analyzing Holes in Plates, Drilling

Components, Creating Distributed Drill Component, Drilling

Lists, Catalogs, Adding user Catalog, Linking user Catalog to

Another, Applying user Catalog, Generating the Bill of

Material, Using Drafting Functionalities |

* Mold

Tooling Application – 90 mins

Power copies, User defined features, Product

knowledge templates, Creation, instantiation and cataloging

* Mold Tooling in NC - PMG, SMG, AMG

– 120 mins

* User questions and wrap up - 30 mins. |

Download Training Course Brochure..>>

For complete course schedules and pricing, kindly

contact us at:

training@camcoe.com

|